Description

Ultrasonic Dust Suppression Systems

Dust suppression systems are an ever-growing need within the industry to combat the harsh and dangerous air Dust particles that are present in underground environments, we at One Industries have listened to our customers’ requirements and have worked vigorously with them to come up with a solution to help solve the dust problems in key targeted areas to keep underground personnel safe.

One Industries designed and manufactured ultrasonic dust suppression units. Our units are now widely used in underground coal.

Our units are housed in compact stainless-steel cabinets and use high quality components.

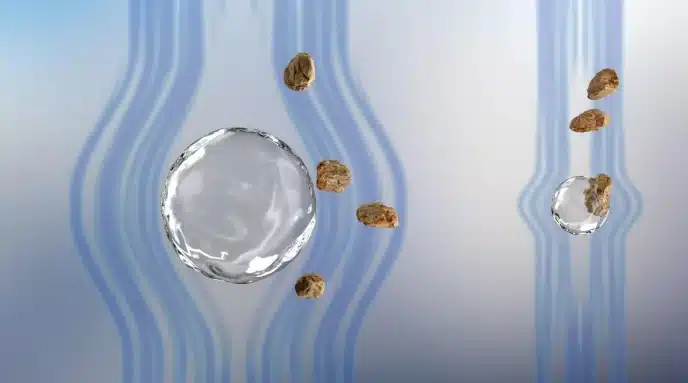

The ultra-sonic dust suppression units use Air and water atomisation technology to atomise the water, this makes it the best means of use for dust suppression.

Our units use as little as 7.1 litres of water per hour making it perfect for underground conveyor transfers points when keeping water control to a minimum is Key.

The standard units come in a range from 1 to 6 nozzles and can also be optioned to include transducers to monitor pressures and solenoids to remotely turn the units on and off. These solenoids can also be controlled using set programming in the sites PLC control.

We can also customise a unit to control all services at a conveyor transfer point, and dust suppression control is now possible from one neat unit.

Warranty

One Industries warrants all their products to be free of defects both in materials and workmanship for a period of 12 months from the date of invoice. The warranty given by One Industries will extend only to replacing or repairing product shown to be defective.

The warranty is subject to the following restrictions:

(a) Installation of the product contrary to the instructions contained in this manual will void such warranty absolutely;

(b) The warranty will not extend to any liability for injuries incurred and which result from the use of the product contrary to the instructions in the manual;

(c) Except as prescribed by law, One Industries will not be liable for any damage sustained by a purchaser or a third party by way of consequential loss arising out of defects in the product;

(d) Consumable components subject to normal wear and tear are not covered in this warranty;

(e) No unauthorised alterations are to be undertaken to the product.

Spare Parts

This is the recommended spare parts to be carried onsite

- WATER FILTER

- 6mm Hose

- 10mm Hose

- PRESSURE GAUGE LARGE 200 PSI

- 1/2″ SOLENOID VALVE MANUAL OVERRIDE

- SOLENOID VALVE COIL 24V

- PRESSURE REGULATOR

- ULTRA SONIC NOZZLE

- AIR PRESSURE GAUGE 100 PSI